易客发Arkitex Verispress软打样非常适合Radin Print

Radin Print自1995年成立以来一直提供高质量的杂志,书籍,目录,传单和小册子。该公司战略总部位于克罗地亚首都萨格勒布西部的Sveta Nedelja,采用最新技术保持创新的前沿,通过无缝的工作流程实现令人印象深刻的印刷操作。

凭借对卓越和创新的承诺,创始人Marijan Arambašin和Branka Pušec已将Radin Print发展成为国际行业领导者,不仅在克罗地亚,而且在塞尔维亚和阿尔巴尼亚建立了最先进的印刷设施。此外,还在罗马尼亚、匈牙利、波斯尼亚和黑塞哥维那、黑山、奥地利、德国、丹麦、意大利等地设立了分公司。

“很长一段时间以来,我们一直在寻找一种软打样应用。在ECO3的一家报纸客户那里看到令人印象深刻的现场演示后,我们很快意识到verpress非常适合我们的需求。”

——ALEN GIZDAVIC, 技术总监 – RADIN PRINT

Radin Print已经依靠ECO3的Apogee工作流管理软件超过23年,设置了四个rip来处理大量的工作。此外,这家克罗地亚公司还将Apogee WebApproval整合为在线协作工具,以实现顺畅高效的文件交付和最终客户对艺术品的批准。最近,Radin通过Arkitex Enhance Veripress软打样成功扩展了这一自动化工作流程,在提高内部印前效率的同时,也提高了可持续性并节省了成本。

作为管理Radin生产过程的Apogee工作流程的延伸,Arkitex Enhance Veripress提供了一个完整的印刷打样系统,提供软打样作为成品印刷品的精确数字表示。这一创新软件的实施使公司能够在屏幕上产生经过验证的,颜色匹配的样张,只需按一下按钮,即可实现全面的质量控制。

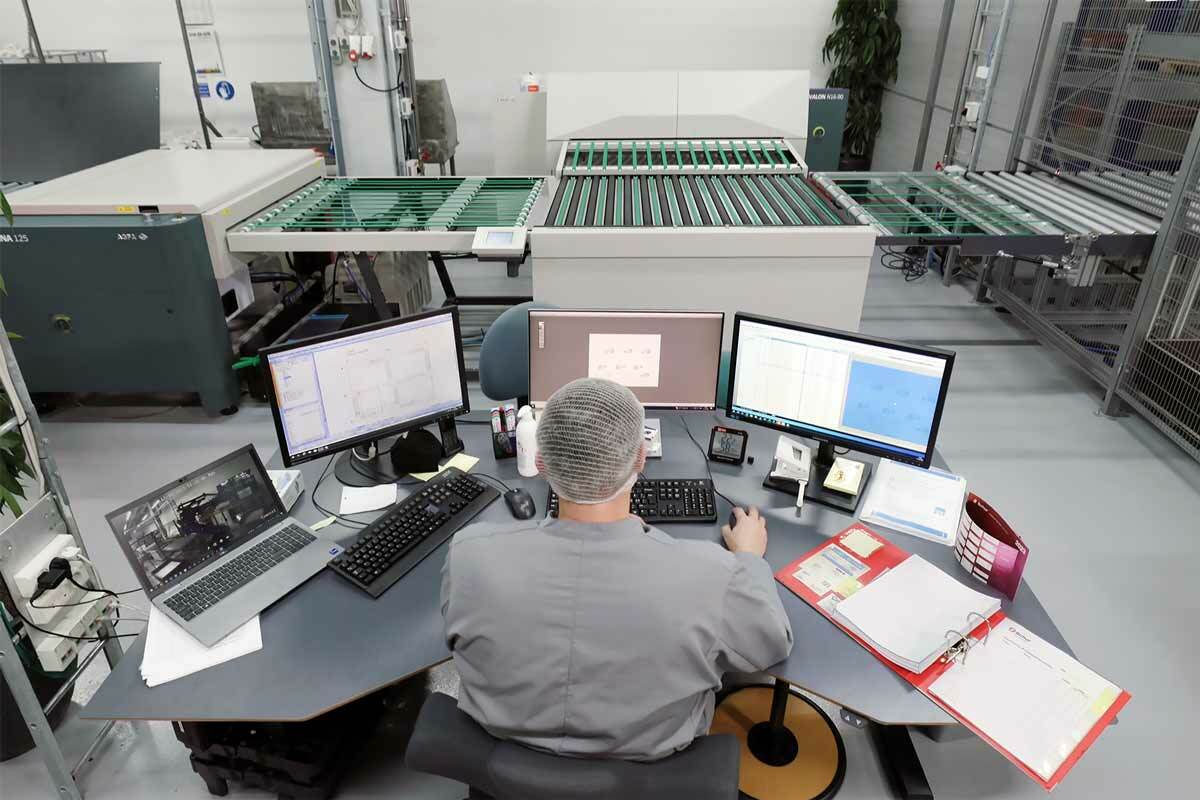

Alen Gizdavcic, Radin Print 技术总监(右) 和 Karl Wolf,易客发售前顾问

“易客发Verispress的主要优点是可以精确地在屏幕上模拟打印页面,并具有准确的颜色匹配。这让你十分放心,一旦印版交付,你的软样稿就可以打印了。”

易客发Verpress系统可以并行处理多个页面,通过高响应的触摸屏显示器轻松访问结果。提供了一键访问,一套全面的工具和直观的导航。

“我们与易客发Verpress合作的转变也显著改善了操作员的日常体验。他们现在正在享受快速和全自动内部打样带来的所有好处,使他们的任务变得更加容易。”

—— ALEN GIZDAVIC, 技术总监 – RADIN PRINT

自实施以来,Radin Print已经为其所有产品使用易客发Verispress,这项投资大大加快了内部质量保证过程。转向verispress软打样也降低了硬拷贝打样的成本,成功实现了Radin 80%的目标,并有望进一步节省成本。

Alen Gizdavcic, Radin Print技术总监 (左) 和 Arnold Posch, 易客发SEE分公司经理

对易客发Arkitex verpress的投资是Radin致力于推进一流技术,提供卓越打印质量和提供卓越客户服务。它也完全符合公司的可持续发展目标,即通过优化流程和节省材料来减少浪费。因此,Radin继续引领印刷行业,制定新的质量标准,确保为客户和环境创造更美好的未来。